Technical cooperation

Acquire the Unique Capabilities

OCR has demonstrated the capacity to establish Build, Operate, Transfer (BOT) facilities in partnerships with international governments and commercial partners. Our solutions contribute to critical national or regional defense infrastructure creation by:

- Developing a knowledge-based economy

- Diversifying the economy

- Growing the country's industrial base

- Creating business opportunities for the private sector

- Generating high-value exports

- Creating jobs

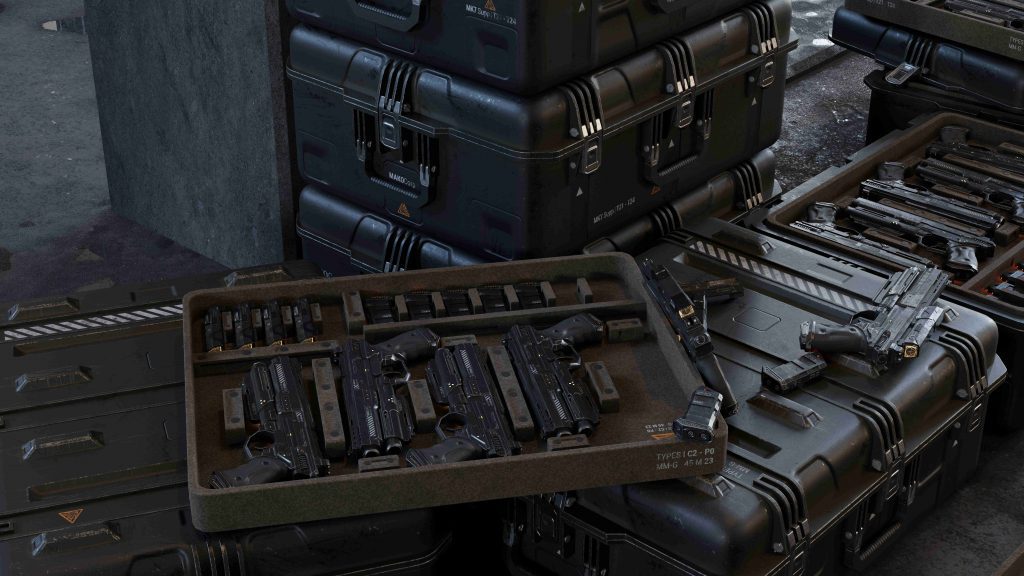

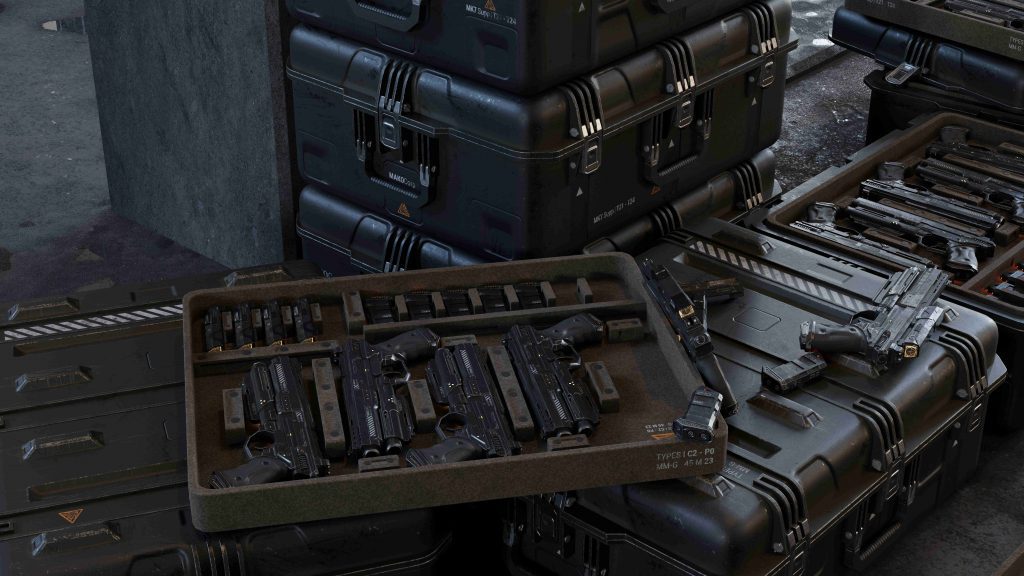

We offer our competences to establish manufacturing factories as well as storage, testing and training facilities. As a result, our clients acquire years of experience in manufacturing and supplying both NATO and Non-Standard ammunition, weapons and accessories.

scope of expertise

- Due diligence, including business plan, financial assessments, and production and procurement planing

- Transfer of Technology (ToT), Transfer of Production (ToP), Certification and Qualification (C&Q)

- Facility design, engineering and construction

- Source and acquire state-of-the-art systems, machinery and technology

- Implementation of purchasing system with supplier qualification methodologies

- Specialized training to Transfer of Knowledge (ToK)

- R&D programs and innovation

- Daily manufacturing management (if required)

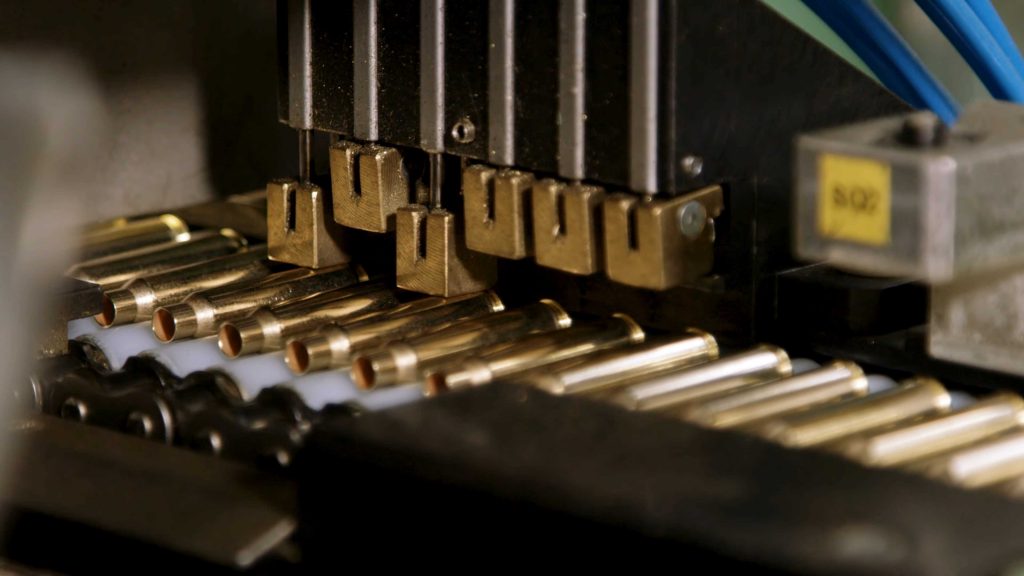

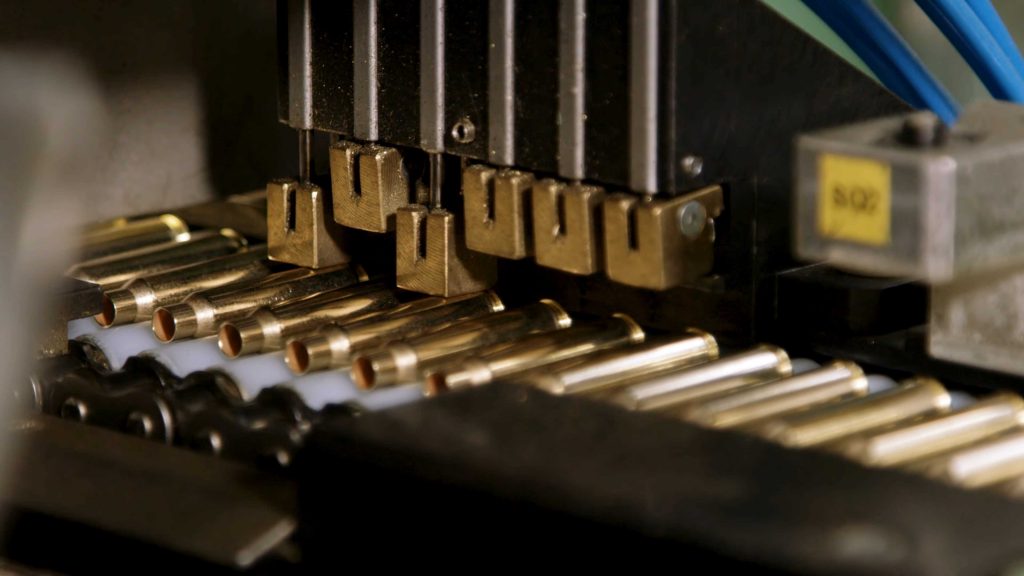

Ammunition

Advantages

- Low life-cycle cost

- High return on investment

- Optimized production

- Support in developing a global sales strategy and supply chain excellence

- Highest quality products and multidisciplinary testing practices

- Expertise in manufacturing, sourcing and integrating NATO and Non-Standard munitions

OCR cooperates with governments and partners and leads the Design, Build, Operate, Transfer and Manage (DBOTM) of the ammunition or weapon production centers to fulfill local and regional demands. We offer a wide range of services and adjust cooperation models based on the client’s objectives. Our solutions help governments to establish local production facilities which, in turn, strengthens the pre-existing military industry, decreases dependency on imports, increases exports, creates new jobs, and gives preference to local subcontracting.

OCR has nearly 15 years of proven performance supporting the U.S. and international defense and security missions with specialized production, procurement and complex logistics services across six continents. Our management and production teams are talented industry leaders with unique business and marketing capabilities. We work with our clients from the very early stages of their projects and support them in various program aspects such as:

- Business plan and financial feasibility

- Capacity planning

- Support in licensing and certifications

- Supply chain planning and sourcing

- R&D and project continuity

OCR partners with its sister companies and trusted international partners to provide clients with turnkey solutions to design and build state-of-art ammunition and weapons complexes. Being a shareholder of numerous leading ammunition and weapons factories in four continents, OCR understands the requirements, regulations and production planning aspects including, but not limited to:

- Facility planning

- Design and detailed engineering

- Machinery and equipment

- Advanced infrastructure

- Smart city and automation solutions

OCR offers management of the entire buildout and day-to-day operations of the ammunition complex while ensuring it is developed in accordance with ISO 9001 quality standards of manufacturing.

Construction

management

- Engineering, construction and operation of a turnkey facility

- Managing a phased approach to facility construction, in accordance with ISO and local standards

- Management of procurement stages, from raw materials to production readiness

- Safety implementation, QA standards, hazardous materials and energetics

- Environmental impact studies

- Upgrade of existing facilities (if applicable)

supply

chain

- Implementation of project management and scheduling processes

- Application of ISO standards to manufacturing processes

- Production rollout and testing readiness standards

- Integrated Logistics Support (ILS)

- Day-to-day production, procurement processes and workforce training

- Facility maintenance and code of compliance

- Auditing of operational cost efficiencies and processes

operations

management

- Implementation and management of procurement processes

- Basic Ordering Agreements (BAO) and partner relations

- Warehouse setup and management, process-flow and storage

- Implementation of receiving and acceptance process for materials, equipment and energetics

- Material flow and work order controls, ERP

- Optimized operations using PMBOK disciplines

OCR offers flexible cooperation models for production of ammunition and weapons. We are knowledgeable and experienced in:

- Transfer of Knowledge (ToK)

- Transfer of Technology (ToT)

- Transfer of Production (ToP)

- Technical Data Packages (TDP)

- Specialized training

- Development of capabilities in R&D

OCR’s Technical Data Package (TDP) provides design, development, production and maintenance for a range of small, medium and large caliber ammunition and weapons (NATO and Non-Standard). Transfer of knowledge, production and technology ensures turnkey production that results in job creation, growth of the local defense industry, while assuring the “security of supply” for the domestic industry.

transfer of production

- Equipment setup and training

- Supply chain establishment

- Manufacturing processes

- Tools, gauges and automated systems

- Management of daily operations

- Post-transfer audits and instructions

- Testing software

transfer of technology

- Ammunition TDPs for small to large caliber ammunition and/or weapons

- Facility blueprints for small to large caliber ammunition and/or weapons

- Equipment listing and engineering, outfitting plan

- Quality standards: Non-Standard and NATO

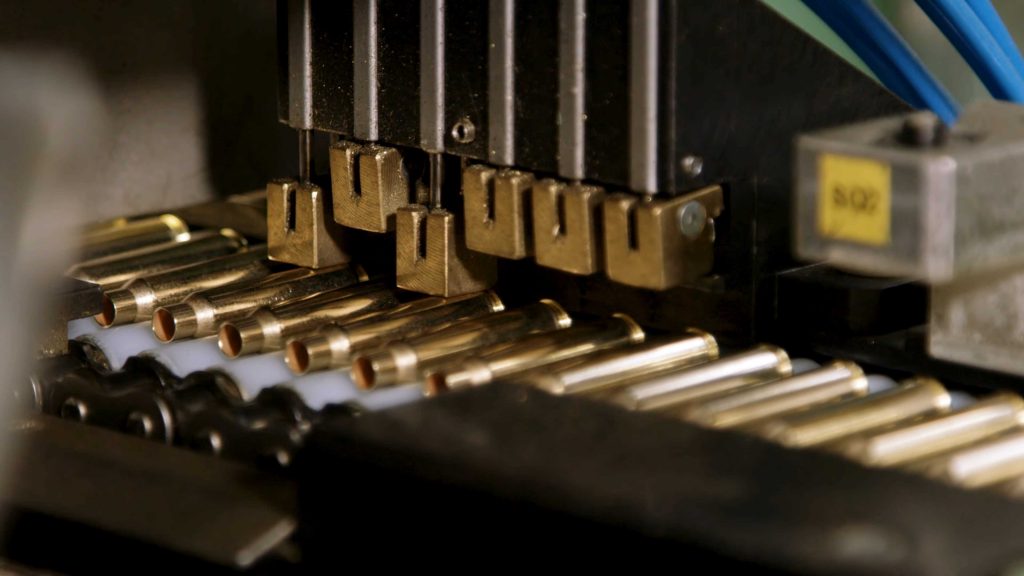

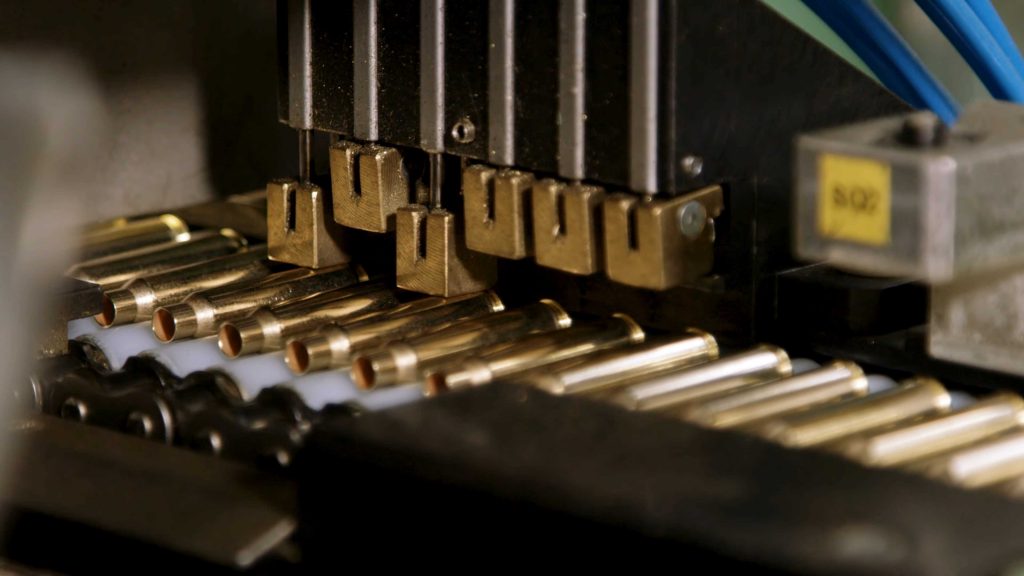

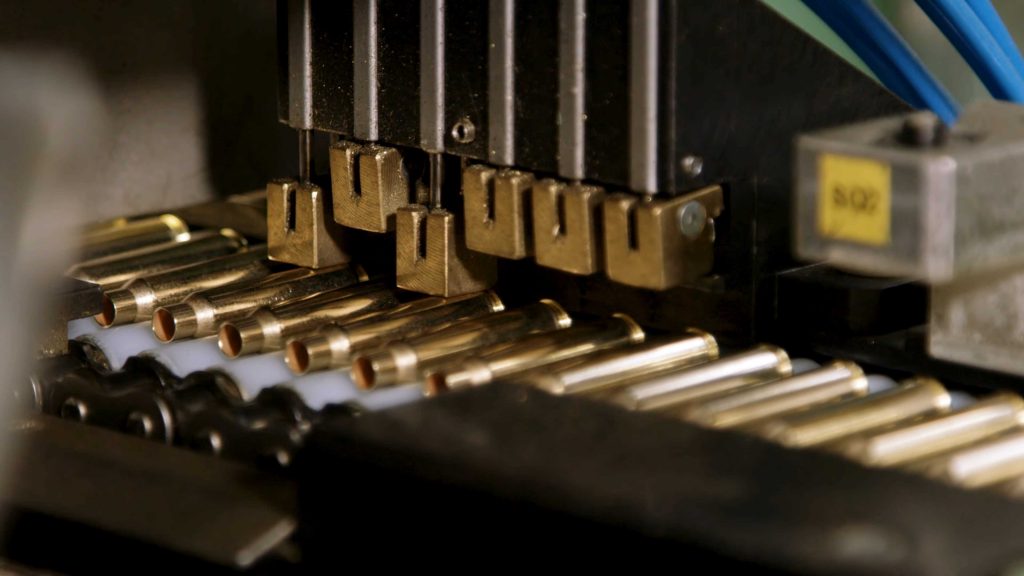

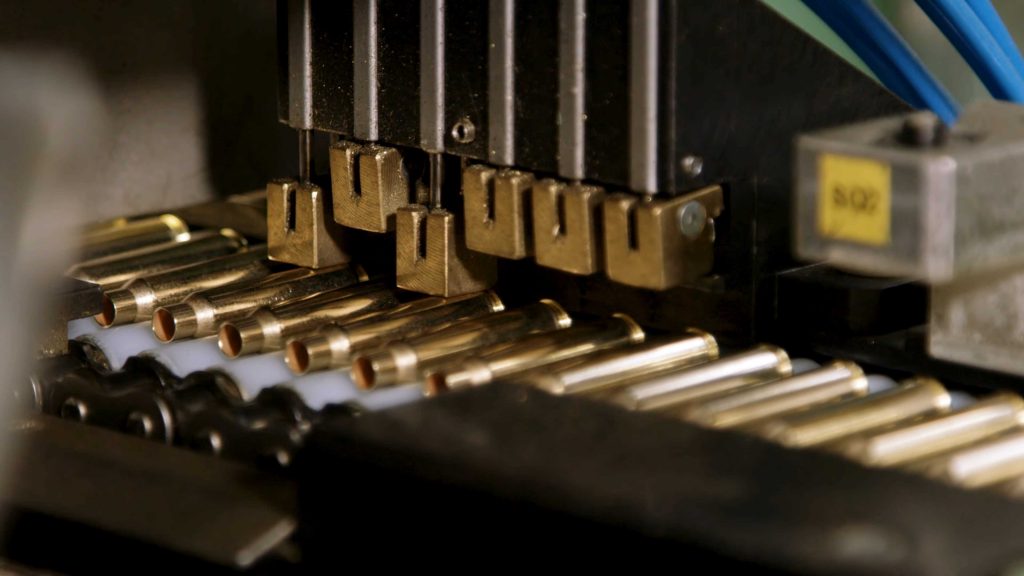

Ammunition factories require very specialized equipment to produce quality, based on NATO and AQAP-2110 standards. OCR’s clients acquire the knowledge and specifications for such requirements. We implement LOT testing and quality controls via automated detection systems to ensure target specifications and complete product conformance.

In-Process Production

- Quality Management Systems (QMS)

- Quality Program Plan

- Process Control Documentation

- Statistical Process Control Systems

- Raw Material Certification and Test Reports

- In-process inspection equipment

- ISO/IEC 17025 Calibration/Control Standards

- Random Sampling

Post Production Process

Post production process

- Control and Sampling System

- Ballistics Testing

- Destructive Testing

- First Article Testing

- LOT Acceptance Testing

- Certificate of Conformance

- Process Control Documentation

OCR Training Packages cover multiple disciplines and processes from workforce training to management, and very specific technical skills. In addition to Knowledge Transfer through ToT and ToP packages, we offer:

specialized training

OCR’s SME provided specialized training for local workforce for various disciplines related to ammunition production using its USG approved QAIM (Quality Assurance, Management and Testing) methodology. This training ensures that “key” characteristics of product(s) are measured and recorded throughout ammunition production life-cycle, in-addition, to using in-process and post process systems for each product(s) being offered under OCR’s ToT package.

• Source of Supply

• Raw Materials Validation

• Initial Material Processing

• Assembly and Loading

• Destructive Testing

specialized testing

OCR’s “MIL-SPEC” based testing methodology is also added to training curriculum for additional capability enhancement of local labor; for example, ballistic, metrology, chemical and metallurgical laboratory training allows complete material and product evaluation, where the workforce learn how to test and verify measurements for every lot of ammunition produced. This training ensures conformance and configuration of product specifications are met. Training packages are categorized by products:

• Small Caliber

• Medium Caliber and Mortals

• Large Caliber Weapons

• Weapons (contact us for more information)

R&D areas

At OCR we ensure that all items are produced in accordance with each country’s Ministry of Defense and Military Bureau specifications, employing Quality Management Systems consistent with ISO 9001:2015. We also invest greatly into R&D to develop cutting edge technologies by working on advanced performance designs for small to large caliber ammunition, and build techniques to reduce cost, weight and collateral damage.

Kinetics & Mechanics

- Mechanical design

- Material design & development

Ballistic performance

- Terminal ballistics

- Internal ballistics

- External ballistics

directed energy

- Laser penetration systems

- Pulsed energy projectile

- Systems integration

next generation prototype

- Advanced materials

- Disruptive technologies

Capabilities that set us apart from our competitors:

- Ability to operate in remote and complex environments.

- In-depth knowledge of government and defense contracting.

- A thorough understanding of international management and quality standards.

- Capacity for on-the-ground surge implementation.

- A proven performance history.

- make us a uniquely trusted partner for on-time delivery within budgets.

- Integrated, multi-disciplinary solutions.

- Strategic partnerships with local companies so we can offer our products and services to our customers at a closer proximity to their location. This yields significant cost savings and allows the local partner to provide effective and transparent oversight of any production aspects.

- Expertise in classified environments for the U.S. Department of Defense and Special Operations Command (SOCOM).

OCR has demonstrated the capacity to establish Build, Operate, Transfer (BOT) facilities in partnerships with international governments and commercial partners. Our solutions contribute to critical national or regional defense infrastructure creation by:

- Developing a knowledge-based economy

- Diversifying the economy

- Growing the country's industrial base

- Creating business opportunities for the private sector

- Generating high-value exports

- Creating jobs

We offer our competences to establish manufacturing factories as well as storage, testing and training facilities. As a result, our clients acquire years of experience in manufacturing and supplying both NATO and Non-Standard ammunition, weapons and accessories.

scope of expertise

- Due diligence, including business plan, financial assessments, and production and procurement planing

- Transfer of Technology (ToT), Transfer of Production (ToP), Certification and Qualification (C&Q)

- Facility design, engineering and construction

- Source and acquire state-of-the-art systems, machinery and technology

- Implementation of purchasing system with supplier qualification methodologies

- Specialized training to Transfer of Knowledge (ToK)

- R&D programs and innovation

- Daily manufacturing management (if required)

Ammunition

Advantages

- Low life-cycle cost

- High return on investment

- Optimized production

- Support in developing a global sales strategy and supply chain excellence

- Highest quality products and multidisciplinary testing practices

- Expertise in manufacturing, sourcing and integrating NATO and Non-Standard munitions

OCR cooperates with governments and partners and leads the Design, Build, Operate, Transfer and Manage (DBOTM) of the ammunition or weapon production centers to fulfill local and regional demands. We offer a wide range of services and adjust cooperation models based on the client’s objectives. Our solutions help governments to establish local production facilities which, in turn, strengthens the pre-existing military industry, decreases dependency on imports, increases exports, creates new jobs, and gives preference to local subcontracting.

OCR has nearly 15 years of proven performance supporting the U.S. and international defense and security missions with specialized production, procurement and complex logistics services across six continents. Our management and production teams are talented industry leaders with unique business and marketing capabilities. We work with our clients from the very early stages of their projects and support them in various program aspects such as:

- Business plan and financial feasibility

- Capacity planning

- Support in licensing and certifications

- Supply chain planning and sourcing

- R&D and project continuity

OCR partners with its sister companies and trusted international partners to provide clients with turnkey solutions to design and build state-of-art ammunition and weapons complexes. Being a shareholder of numerous leading ammunition and weapons factories in four continents, OCR understands the requirements, regulations and production planning aspects including, but not limited to:

- Facility planning

- Design and detailed engineering

- Machinery and equipment

- Advanced infrastructure

- Smart city and automation solutions

OCR offers management of the entire buildout and day-to-day operations of the ammunition complex while ensuring it is developed in accordance with ISO 9001 quality standards of manufacturing.

Construction

management

- Engineering, construction and operation of a turnkey facility

- Managing a phased approach to facility construction, in accordance with ISO and local standards

- Management of procurement stages, from raw materials to production readiness

- Safety implementation, QA standards, hazardous materials and energetics

- Environmental impact studies

- Upgrade of existing facilities (if applicable)

supply

chain

- Implementation of project management and scheduling processes

- Application of ISO standards to manufacturing processes

- Production rollout and testing readiness standards

- Integrated Logistics Support (ILS)

- Day-to-day production, procurement processes and workforce training

- Facility maintenance and code of compliance

- Auditing of operational cost efficiencies and processes

operations

management

- Implementation and management of procurement processes

- Basic Ordering Agreements (BAO) and partner relations

- Warehouse setup and management, process-flow and storage

- Implementation of receiving and acceptance process for materials, equipment and energetics

- Material flow and work order controls, ERP

- Optimized operations using PMBOK disciplines

OCR offers flexible cooperation models for production of ammunition and weapons. We are knowledgeable and experienced in:

- Transfer of Knowledge (ToK)

- Transfer of Technology (ToT)

- Transfer of Production (ToP)

- Technical Data Packages (TDP)

- Specialized training

- Development of capabilities in R&D

OCR’s Technical Data Package (TDP) provides design, development, production and maintenance for a range of small, medium and large caliber ammunition and weapons (NATO and Non-Standard). Transfer of knowledge, production and technology ensures turnkey production that results in job creation, growth of the local defense industry, while assuring the “security of supply” for the domestic industry.

transfer of production

- Equipment setup and training

- Supply chain establishment

- Manufacturing processes

- Tools, gauges and automated systems

- Management of daily operations

- Post-transfer audits and instructions

- Testing software

transfer of technology

- Ammunition TDPs for small to large caliber ammunition and/or weapons

- Facility blueprints for small to large caliber ammunition and/or weapons

- Equipment listing and engineering, outfitting plan

- Quality standards: Non-Standard and NATO

Ammunition factories require very specialized equipment to produce quality, based on NATO and AQAP-2110 standards. OCR’s clients acquire the knowledge and specifications for such requirements. We implement LOT testing and quality controls via automated detection systems to ensure target specifications and complete product conformance.

In-Process Production

- Quality Management Systems (QMS)

- Quality Program Plan

- Process Control Documentation

- Statistical Process Control Systems

- Raw Material Certification and Test Reports

- In-process inspection equipment

- ISO/IEC 17025 Calibration/Control Standards

- Random Sampling

Post Production Process

Post production process

- Control and Sampling System

- Ballistics Testing

- Destructive Testing

- First Article Testing

- LOT Acceptance Testing

- Certificate of Conformance

- Process Control Documentation

OCR Training Packages cover multiple disciplines and processes from workforce training to management, and very specific technical skills. In addition to Knowledge Transfer through ToT and ToP packages, we offer:

specialized training

OCR’s SME provided specialized training for local workforce for various disciplines related to ammunition production using its USG approved QAIM (Quality Assurance, Management and Testing) methodology. This training ensures that “key” characteristics of product(s) are measured and recorded throughout ammunition production life-cycle, in-addition, to using in-process and post process systems for each product(s) being offered under OCR’s ToT package.

• Source of Supply

• Raw Materials Validation

• Initial Material Processing

• Assembly and Loading

• Destructive Testing

specialized testing

OCR’s “MIL-SPEC” based testing methodology is also added to training curriculum for additional capability enhancement of local labor; for example, ballistic, metrology, chemical and metallurgical laboratory training allows complete material and product evaluation, where the workforce learn how to test and verify measurements for every lot of ammunition produced. This training ensures conformance and configuration of product specifications are met. Training packages are categorized by products:

• Small Caliber

• Medium Caliber and Mortals

• Large Caliber Weapons

• Weapons (contact us for more information)

R&D areas

At OCR we ensure that all items are produced in accordance with each country’s Ministry of Defense and Military Bureau specifications, employing Quality Management Systems consistent with ISO 9001:2015. We also invest greatly into R&D to develop cutting edge technologies by working on advanced performance designs for small to large caliber ammunition, and build techniques to reduce cost, weight and collateral damage.

Kinetics & Mechanics

- Mechanical design

- Material design & development

Ballistic performance

- Terminal ballistics

- Internal ballistics

- External ballistics

directed energy

- Laser penetration systems

- Pulsed energy projectile

- Systems integration

next generation prototype

- Advanced materials

- Disruptive technologies

Capabilities that set us apart from our competitors:

- Ability to operate in remote and complex environments.

- In-depth knowledge of government and defense contracting.

- A thorough understanding of international management and quality standards.

- Capacity for on-the-ground surge implementation.

- A proven performance history.

- make us a uniquely trusted partner for on-time delivery within budgets.

- Integrated, multi-disciplinary solutions.

- Strategic partnerships with local companies so we can offer our products and services to our customers at a closer proximity to their location. This yields significant cost savings and allows the local partner to provide effective and transparent oversight of any production aspects.

- Expertise in classified environments for the U.S. Department of Defense and Special Operations Command (SOCOM).